Single crystals of semiconductors are macroscopic molecules with periodic repeating foundation models7. In an ideal semiconductor crystal wafer, the atomic location and sort at one level in area repeats itself lots of of microns from one floor to the opposite and lots of of millimetres from one edge to the opposite. In non-polar semiconductors resembling silicon, the crystal orientation is chosen fastidiously to maximise the digital efficiency of gadgets on the floor. Digital gadgets resembling transistors are made solely on one (say, the highest) floor of silicon and never the opposite. Even when the opposite floor was used, the parallel surfaces of a cubic crystal are an identical by symmetry. Because of this flipping a silicon wafer the other way up doesn’t change the chemical or digital properties of the highest floor. Thus, heterostructures and digital gadgets made on the 2 surfaces in an an identical method exhibit an identical properties.

The wide-bandgap semiconductors GaN and aluminium nitride (AlN) have a wurtzite crystal construction with an underlying hexagonal lattice8. This crystal construction breaks inversion symmetry alongside the [0001] orientation (the c axis). The 2 surfaces perpendicular to the c axis of a single-crystal wafer of those polar semiconductors subsequently exhibit very totally different bodily properties: flipping the crystal wafer is analogous to flipping a bar magnet. The chemical properties of the 2 sides are so distinct that they’re used to establish steel or nitrogen floor polarity. Though the metal-polar floor is inert to most chemical substances, the N-polar floor of each GaN and AlN etches vigorously in options with bases, resembling KOH and TMAH, or acids resembling H3PO4 (refs. 9,10).

Giant variations within the digital properties of heterostructures are noticed for the 2 faces11,12. For instance, if an roughly 10-nm-thin coherently strained epitaxial GaN layer is deposited on the N-polar floor of AlN, a two-dimensional electron fuel (2DEG) is fashioned on the GaN/AlN heterojunction quantum properly because of the discontinuity of the conduction band mixed with the discontinuity of the digital polarization throughout the heterojunction13. However when an an identical, roughly 10-nm coherently strained epitaxial GaN layer is deposited on the metal-polar floor of AlN, a 2D gap fuel is fashioned on the heterojunction quantum properly14. These polarization-induced, electrically conductive 2D electron and gap gases are fashioned in crystals nominally freed from chemical impurities resembling donor or acceptor dopants. (Al,Ga)N/GaN HEMTs utilizing such polarization-induced conductive channels exhibit excellent efficiency in high-power and high-speed purposes15,16,17,18.

Thus far, solely a single face of c-axis-oriented GaN single-crystal wafers is used for both photonic or digital gadgets19,20,21. On this work, the 2 polarities on the other faces of a GaN single crystal are mixed to understand a photonic system on one aspect and an digital system on the opposite. A heterostructure quantum properly on the N-polar aspect is used to generate a polarization-induced high-mobility 2DEG and a quantum properly (In,Ga,Al)N p–n diode heterostructure is realized on the other metal-polar aspect. This two-sided wafer is then processed, first into HEMTs on the N-polar aspect, adopted by blue quantum properly LEDs on the metal-polar aspect. Profitable operation of the HEMT and LED gadgets is noticed, permitting the switching and modulation of blue LEDs by HEMTs on the opposite aspect of the wafer.

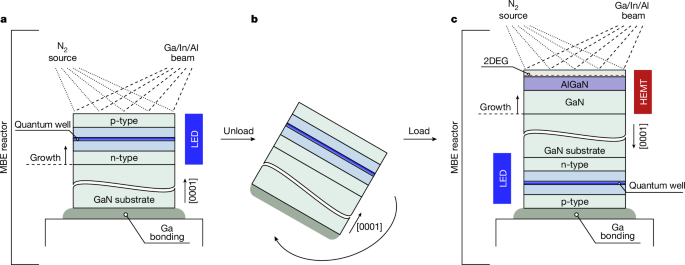

Determine 1 exhibits how dual-side epitaxy for dualtronics was achieved. The beginning wafer is a high-transparency bulk n-type O-doped GaN substrate grown by the ammonothermal technique22,23 with cell electron focus of about 1018 cm−3 and threading dislocation density of about 104 cm−2 with each the Ga-polar and N-polar sides chemo-mechanically polished to acquire atomically easy surfaces. The N-polar floor of the GaN substrate was gallium-bonded to a GaN/sapphire service wafer as proven in Fig. 1a. As a result of the floor bonded to the service wafer must be used once more, we selected gallium bonding to the GaN floor of a GaN/sapphire service wafer to make sure desired components (Ga, N) at this bonding interface. Utilizing molecular-beam epitaxy (MBE), we first grew a blue (In,Ga,Al)N LED construction consisting of a quantum properly energetic area inside a p–n heterojunction on the Ga-polar face of GaN. The wafer was then indifferent from the service wafer and flipped as proven in Fig. 1b. The Ga was faraway from the N-polar aspect and the metal-polar p-type GaN floor of the LED aspect was gallium-bonded on to a clear GaN/sapphire service wafer. Subsequently, a N-polar GaN/AlGaN/GaN heterostructure was grown on the N-polar face once more by MBE to create a high-electron-mobility 2DEG to function the conduction channel of the HEMT, as proven in Fig. 1c. The chosen development situations for the LED and HEMT buildings are described in Strategies.

The gray arrows point out the chronological order of the expansion process. a, Ga bonding of the GaN substrate and MBE development of the (In,Ga,Al)N LED alongside the metal-polar course. b, Unloading, cleansing, flipping, Ga bonding and reloading of the pattern. c, MBE development of the GaN/AlGaN HEMT alongside the N-polar course.

Determine 2a exhibits the exact layer thicknesses and compositions of the HEMT on the N-polar aspect on the highest and the LED on the metal-polar aspect on the underside of the one GaN wafer achieved after the dual-side epitaxy. Determine 2b–g exhibits the corresponding scanning transmission electron microscopy (STEM) photographs.

a, Schematic exhibiting the HEMT-LED heterostructures grown on each faces of a single-crystal c-plane n-GaN substrate. b, HAADF-STEM picture exhibiting the GaN/Al0.40Ga0.60N/GaN HEMT. Scale bar, 10 nm. c, Atomic-resolution picture akin to the uppermost GaN/Al0.40Ga0.60N heterojunction interface that hosts the 2DEG. Scale bar, 2 nm. d, iDPC picture within the uppermost GaN layer of the HEMT indicating that the nitrogen polarity follows that of the substrate to the floor. Scale bar, 1 nm. e, HAADF-STEM picture exhibiting the LED quantum properly, electron blocking layer, cladding and speak to layers. Scale bar, 100 nm. f, Atomic-resolution picture akin to the LED In0.07Ga0.93N/In0.17Ga0.83N/In0.07Ga0.93N single quantum properly. Scale bar, 2 nm. g, iDPC picture of the p-InGaN contact layers of the LED indicating that the steel polarity follows that of the substrate. Scale bar, 1 nm.

The MBE-grown HEMT on the N-polar aspect began with the expansion of a 500-nm-thick unintentionally doped (UID) GaN buffer layer as proven in Fig. 2a, adopted by 5-nm GaN:Si and 5-nm Al0.40Ga0.60N:Si layers with a Si focus of three × 1018 cm−3 capped with undoped 15-nm Al0.40Ga0.60N and 10-nm GaN. Silicon doping under the 15-nm AlGaN layer was used to stop the formation of a polarization-induced 2D gap fuel on the backside N-polar AlGaN/GaN interface24. The majority power bandgap of GaN is Eg1 = 3.4 eV and that of Al0.40Ga0.60N is Eg2 = 4.5 eV at room temperature. For the N-polar HEMT, the high-angle annular dark-field (HAADF) STEM picture in Fig. 2b exhibits the 20-nm AlGaN layer close to the floor with sharp interfaces with GaN on either side. Determine 2c zooms in to indicate the lattice picture of the highest GaN/AlGaN heterojunction, wherein the 2DEG resides totally on the GaN aspect. A pointy heterointerface between GaN and AlGaN is noticed, with the atomic planes clearly resolved. Determine second exhibits an built-in differential part distinction (iDPC) picture of the GaN HEMT channel layer, proving the N-polar crystal construction alongside the expansion course: the N atoms situated vertically under the brighter Ga atoms.

For a N-polar heterostructure, a cell 2DEG is anticipated to kind on the GaN aspect inside a triangular quantum properly fashioned by the conduction band offset ΔEc ≈ 0.8 eV on the sharp GaN/AlGaN heterojunction seen in Fig. 2c. A Corridor-effect transport measurement described in Strategies confirmed {that a} 2DEG is fashioned with room-temperature electron density ns ≈ 1.26 × 1013 cm−2 and electron mobility of μ ≈ 1,970 cm2 (V s)−1, leading to a sheet resistance of Rsh = 1/(ensμ) ≈ 252 Ω sq−1, wherein e is the magnitude of the electron cost. The noticed sheet resistance is the bottom and the electron mobility is among the highest amongst all N-polar HEMT heterostructures reported within the literature, ensuing largely from low interface roughness scattering of the quantum-confined electrons on the sharp interface owing to the high-quality epitaxy on the double-side polished bulk GaN substrate25,26,27. A benchmark comparability with state-of-the-art N-polar III-nitride HEMTs reported within the literature is proven in Prolonged Knowledge Fig. 1.

The MBE-grown LED heterostructure on the metal-polar aspect seen on the underside aspect of Fig. 2a consists of a 150-nm GaN:Si buffer layer, adopted by a 50-nm In0.07Ga0.93N/40-nm In0.07Ga0.93N energetic area with a single 2.5-nm-thick In0.17Ga0.83N quantum properly embedded in between.

This photonic energetic area was adopted by p-type doped layers beginning with a 20-nm Al0.09Ga0.91N electron blocking layer with a Mg focus of three × 1019 cm−3, adopted by a 150-nm-thick GaN layer with a Mg focus of 6 × 1018 cm−3. This LED heterostructure was capped with p-InGaN contact layers consisting of 40-nm-thick In0.02Ga0.98N and 5-nm-thick In0.15Ga0.85N doped with Mg on the ranges of 1 × 1020 cm−3 and 5 × 1020 cm−3, respectively, to kind low-resistance ohmic contacts for gap injection into the LED energetic area, whereas concurrently being clear to the sunshine emitted from the energetic area. Determine 2e exhibits a HAADF-STEM picture of every of those LED layers, indicating a uniform quantum properly and the encircling energetic area alongside the airplane of the wafer. The atomically resolved picture in Fig. 2f exhibits the two.5-nm-thick In0.17Ga0.83N quantum properly and the InGaN cladding layers. The group III component fractions and doping profiles for each the LED and HEMT buildings are introduced within the time-of-flight secondary ion mass spectrometry (ToF-SIMS) knowledge proven in Prolonged Knowledge Fig. 2, which point out that the measured values are as supposed. Notably, there isn’t a noticeable interdiffusion of dopants or group III broadening of the metal-polar LED layers, indicating that interface and doping management isn’t affected by the second development step.

Determine 2g exhibits an iDPC picture of the p-InGaN contact layers on the metal-polar LED aspect. The LED is certainly metal-polar considered within the development course with the substrate out of view above. This confirms that the polarity of the crystal substrate locks the polarity of the epitaxial layers and that the crystalline registry goes via everything of the GaN wafer over lots of of microns. Because of this the 2DEG types on the N-polar aspect of the wafer, whereas the steel polarity is retained all through the energetic areas, quantum properly and electron blocking and speak to layers of the LED. The high-crystalline perfection of the LED heterostructure additionally proves that the expansion of the HEMT heterostructure on the N-polar aspect at a excessive temperature and with nitrogen plasma doesn’t destroy or degrade the LED construction through the slightly harsh thermal and chemical situations. The floor of the as-grown heterostructures after the completion of each epitaxial steps as proven in Prolonged Knowledge Fig. 3 exhibit sub-nanometre roughness atomic steps attribute of step-flow development, indicating the profitable dual-side epitaxy. X-ray diffraction (XRD) measurements point out excessive crystallinity, sharp heterointerfaces and coherently strained layers to the GaN substrate seen in Prolonged Knowledge Fig. 4.

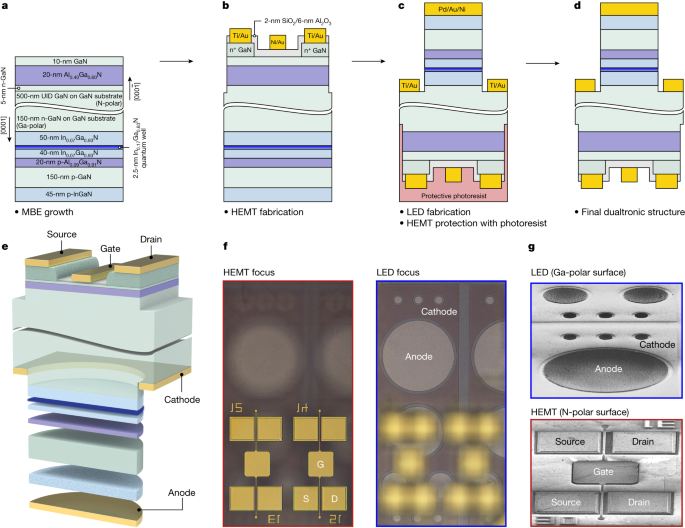

For profitable dualtronics, the survival of the skinny LED heterostructure layers through the epitaxial development situations of the HEMT aspect must be replicated for the steps of system fabrication. The N-polar floor is especially troublesome to guard chemically as a result of it reacts strongly with a number of options which might be usually used for floor cleansing and conditioning through the processing steps. For instance, the pure etching of the N-polar floor of GaN in options of KOH, TMAH or H3PO4 kind pyramidal sides that considerably roughen the pristine, flat floor9. This property of floor roughening is put to good use for environment friendly mild extraction in blue LEDs. However such roughening would destroy the N-polar HEMT desired right here, which requires sub-nanometre smoothness to protect the high-mobility 2DEG and for the fabrication of supply, drain and gate electrodes. Determine 3 exhibits the process used for the fabrication of the HEMT and LED on the other sides of the identical wafer, together with the ultimate dualtronic system. A extra detailed overview schematic of the fabrication of the dualtronic system is proven in Prolonged Knowledge Fig. 5.

a–d, Machine processing move for the double-sided HEMT-LED. Ranging from the as-grown heterostructures, the gray arrows observe the impartial processing steps chronologically, with the metal-polar LED being processed after the N-polar HEMT. e, A 3D illustration of the whole system. f, Optical microscope photographs of the as-processed pattern, centered on the LEDs (proper) and on the HEMTs (left). The N-polar HEMTs are oriented upwards, forming the uppermost floor. For scale, the diameter of the big LED anode contact is 140 μm. g, Scanning electron microscope photographs of the HEMTs on the N-polar GaN floor (backside) and the LEDs on the metal-polar GaN floor (prime).

Determine 3a exhibits the beginning layer construction, which is first processed right into a HEMT on the N-polar aspect proven in Fig. 3b. Ti/Au low-resistance supply and drain ohmic contacts are fashioned on regrown GaN layers which might be closely n-type doped with silicon. A skinny gate SiO2/Al2O3 dielectric layer was deposited, adopted by a Ni/Au gate steel stack to finish the HEMT fabrication. The HEMT layer was then protected by a photoresist coating and flipped the other way up to the metal-polar aspect up for LED fabrication for every photolithography step.

Determine 3c exhibits that, for the fabricated LED, Pd/Au metallization was used for the p-type anode contact. The high-work-function steel palladium aligns the steel Fermi degree near the valence-band holes of the p-type doped InGaN cap layer of the LED aspect. The skinny p-InGaN reduces the contact resistance by enhancing the free gap focus and by lifting the valence-band power most. To kind the n-type cathode contact, mesa areas have been etched by eradicating all the energetic area and terminating the etch on the buried n-type GaN layer to disclose a flat floor. Ti/Au steel stacks have been deposited on this flat n-GaN floor to kind a low-resistance contact between electrons on the Fermi floor of the steel and the electrons within the GaN conduction band.

Determine 3d exhibits the finished dualtronic construction after elimination of the protecting photoresist coating and Fig. 3e exhibits a cross-section of it flipped the other way up. This schematic emphasizes the single-crystal nature of the entire construction, throughout the majority of the wafer indicated by the wavy break within the thick GaN layer between the HEMT on the highest and the LED on the underside. Determine 3f exhibits an optical microscope picture centered on the highest HEMT floor on the left and the underside LED centered on the precise. The room-temperature power bandgap of the majority wafer between the HEMT and LED mesas is Eg1 = 3.4 eV of GaN, which is optically clear to seen mild, permitting for imaging of the LEDs via the wafer from the HEMT aspect as seen in Fig. 3f. This additionally emphasizes that the transistor layers are clear to seen wavelengths and are subsequently enticing for dualtronic integration with LEDs as clear thin-film transistors (TFTs) however, as seen later, with a lot increased efficiency than present TFTs made from oxide or natural semiconductors. Determine 3g exhibits the scanning electron microscope photographs of the HEMTs on the N-polar GaN floor (backside) and the LEDs on the metal-polar GaN floor (prime).

Determine 4a exhibits the measured switch attribute and transconductance of the N-polar HEMT. A threshold voltage of VT ≈ −3 V is measured with an on-current drive exceeding 1 A mm−1 at a drain voltage of VDS = 5 V and gate voltage of VGS ≈ 3 V. The transistor transconductance gm = ∂ID/∂VGS peaks at VGS ≈ −1.6 V. Determine 4b exhibits the measured ID–VDS output traits of the HEMT for varied gate voltages overlaid with the LED present–voltage traits. The transistor delivers sufficient output present to drive the LED with variable drive currents managed by the gate voltage as much as 50 mA or extra. Determine 4c exhibits the LED present and the HEMT present for VDS = 5 V within the logarithmic scale, indicating that the HEMT can management the LED present and therefore its optical output depth over a number of orders of magnitude. Determine 4d exhibits the measured output spectra of the LED for injection present densities starting from 1 to 140 A cm−2. The emission depth will increase with the injection present density and the height emission wavelength blueshifts from λ ≈ 470 nm at 1 A cm−2 to λ ≈ 450 nm at 140 A cm−2 within the blue regime of the seen spectrum. The blueshift is attributable to screening of the interior polarization fields, which end in a lowered quantum-confined Stark impact, in addition to the Burstein–Moss impact. The inset in Fig. 4d exhibits the brilliant blue electroluminescent glow of the blue LED barely under the centre of the wafer on the metal-polar aspect. The output and switch traits of the HEMTs earlier than and after the fabrication of the LEDs are proven in Prolonged Knowledge Fig. 6. It was confirmed that, after the LED processing, there was minimal degradation of the HEMT with a lower than 0.3 V threshold voltage shift and negligible change within the output and gate leakage present. This minimal degradation highlights the feasibility of utilizing double-side epitaxy and processing for dependable heterogeneous system integration on each crystal faces.

a, Normalized drain present (black line) and transconductance (gray line) of an N-polar HEMT as a perform of gate-source voltage, working at a drain-source voltage of 5 V. b, Linear plot exhibiting the household of curves for a HEMT (black strains) for a gate-source voltage starting from 1.75 (on) to −3.25 V (off). On the precise axis, the linear present–voltage traits of a 400-μm-diameter LED (blue line) and unnormalized output traits of a HEMT are proven as properly. The scale of the measured HEMTs are LSD = 4 μm, LG = 1.5 μm and WG = 50 μm. c, Semi-log plots exhibiting the unnormalized drain present (stable black line) and gate present (dashed black line) versus gate-source voltage, for a drain-source voltage of 5 V. Right here the transistor present corresponds to the left vertical axis. The horizontal dashed black line signifies a normalized channel sheet present density of 1 A mm−1. Equally, akin to the precise vertical axis is the LED present (blue line) as a perform of ahead bias for a 400-μm-diameter system. d, Electroluminescence spectra of a metal-polar, 400-μm-diameter LED. The injection present density ranges from 1 to 140 A cm−2. The inset exhibits a digital camera picture of the pattern with an LED within the on state. a.u., arbitrary models.

Determine 5a exhibits the layer buildings and corresponding energy-band diagrams of the HEMT on the left and the LED on the precise when they’re linked within the circuit format proven in Fig. 5b. The supply of the HEMT is linked to the anode of the LED to inject present to mild up the LED. The sunshine emitted from this dualtronic system is measured with a photodiode. A custom-made probe setup was fabricated to probe each HEMTs and LEDs with out the necessity to flip the pattern, proven schematically in Prolonged Knowledge Fig. 7. When the gate voltage of the HEMT is decrease than the transistor threshold (VGS VT), the triangular quantum properly is lifted above the Fermi degree within the energy-band diagram of the HEMT as proven and the transistor is off. The corresponding energy-band diagram of the LED is proven on the precise. When the HEMT gate voltage is above threshold, the underside of the triangular quantum properly is pulled under the Fermi degree, as seen in Fig. 5a, flooding the GaN/AlGaN interface with electrons that kind a 2DEG channel. The output present flowing from the drain of the HEMT is then injected into the cathode of the LED, ahead biasing it to the energy-band diagram proven and indicated by the cut up quasi-Fermi ranges of electrons Efn and holes Efp. The electrons injected from the cathode radiatively recombine with the holes injected from the anode into the In0.17Ga0.83N quantum properly, emitting mild that’s sensed by the photodiode.

Determine 5c exhibits that the photovoltage sign follows the gate voltage as it’s swept between −3.0 ≤ VGS ≤ 3.6 V with the drain voltage set at a voltage of 5.9 V and the back-gate voltage set at a voltage of 1 V, over the millisecond timescale throughout its threshold voltage from the on state to the off state. Determine 5d exhibits that, when the gate voltage of the HEMT is modulated within the vary 2.0 ≤ VGS ≤ 3.0 V when it’s in its on state with VGS > VT, the sunshine emitted by the LED follows this gate modulation, translating the digital sign within the gate of the HEMT right into a photonic vibrant and dim sign output from the LED on the opposite aspect of the wafer. The on–off modulation of the dualtronic system could be improved by utilizing related ideas as used for conventional LEDs28,29.

a, Power-band diagrams of the HEMT and LED indicating the on and off states. b, Circuit schematic of the monolithic HEMT-LED, bearing in mind the back-gating impact of the conductive GaN substrate. c,d, Monolithic switching measurements, modulating between on and off (c) and between vibrant and dim modes (d). The gate-source modulation voltage is proven in crimson, the photodiode voltage whereas modulating the LED in stable blue and the background (LED off state) photodiode voltage in dashed blue. a.u., arbitrary models.

Owing to the dualtronic construction, the cathode of the LED also can function a again gate for the HEMT, which was taken into consideration within the monolithic switching measurements. With a separate contact to the n-GaN substrate, we noticed that the cathode voltage may exponentially management the drain present when the highest gate was electrically floating. This back-gating impact is accessible as a brand new performance or could also be eradicated if undesirable by changing the conductive substrate with a semi-insulating substrate. The back-gating impact of the HEMT with the LED is proven in Prolonged Knowledge Fig. 8.

The observations described right here thus show that the idea of dualtronics is possible, opening the paths for a lot of fascinating potentialities. This work realized an electronics material on the N-polar face and a photonic material on the metal-polar face of the identical wafer. This dualtronic mixture is of speedy curiosity for combining microLEDs on the photonic aspect with clear TFTs on the identical GaN wafer on the opposite aspect. This monolithic convergence of gadgets reduces the variety of parts required for microLEDs, with the potential for substantial space and price financial savings owing to environment friendly use of the substrate actual property. Furthermore, monolithic integrating schemes combining transistors and LEDs on a single substrate face depend on a number of epitaxial layers that have to be both selectively eliminated and/or regrown to show the LED heterostructure buried beneath the transistor construction or vice versa30,31,32,33,34,35,36,37. Exposing the buried heterostructure by dry etching induces plasma harm, resulting in diminished mild emission and degradation of contacts. Equally, with a selective development technique, the ex situ nature of regrowth leads to a poor development interface, rising leakage pathways. These points are all prevented with the dualtronics integration scheme.

The dualtronics idea extends to a number of thrilling new alternatives. The metal-polar face of the substrate, to benefit from excessive emission efficiencies, can be utilized for any optoelectronic system resembling laser diodes, semiconductor optical amplifiers and electro-optical modulators, whereas transistors or photodetectors are fabricated on the N-polar face. This full use of the substrate markedly decreases the variety of parts and chips wanted in photonic built-in circuits. For different purposes, each GaN polarities can be utilized. As an illustration, RF transistor energy amplifiers for the transmit a part of communication programs could be realized on one polarity and low-noise amplifiers for the obtain finish of communication programs can allow built-in transceivers in a mixed transmit/obtain module of smaller kind issue than present programs. The mixture of n-channel transistors on one polarity with p-channel transistors on the other polarity can allow new types of complementary transistor circuit topologies linked by through-vias via the substrate. Such dualtronic gadgets can benefit from the wide-bandgap nature of the polar nitride semiconductors for brand spanking new types of energy electronics and RF electronics. These, and several other allied potentialities, can permit for the creation and manipulation of electrons and photons on the other faces of the identical wafer to attain new functionalities.

The ultrawide-bandgap polar semiconductor AlN boasts giant electro-acoustic coupling, which makes it the popular materials as we speak for acoustic-wave RF filters. Dualtronics can thus benefit from this property of the polar nitride semiconductors to mix sonar (by sound waves), radar (microwaves) and lidar (mild) on the identical platform.

The environment friendly use of the substrate surfaces eliminates wasted area, reduces the power and materials prices of manufacturing a number of wafers and thus must be of nice curiosity for future applied sciences properly past the actual polar semiconductor supplies mentioned right here.